Author: James Roberts

Label Printer Sales Specialist at HUB Auto ID Ltd

In today's fast-paced business environment, the importance of selecting the right printing equipment and supplies cannot be overstated. Whether it's choosing Direct Thermal, or Thermal Transfer printers, opting for Paper, Synthetic or Specialist Labels, and using Wax, Resin, or Wax/Resin ink ribbons - each component plays a crucial role in ensuring efficient and productive print operations.

In this blog, we will explain the differences in all these components to help your business choose the best type for your needs while explaining the differences and the myriad of benefits that businesses can reap by getting these correct. Here at HUB Auto ID we pride ourselves on over 25 years’ experience in the industry of helping businesses find the right label print solution for them.

Print Methods:

Thermal transfer and direct thermal printing are the two common methods used for printing information onto labels, tags, receipts, and other types of media. While they both utilize thermal technology, they differ slightly in the way they produce images onto the printing material.

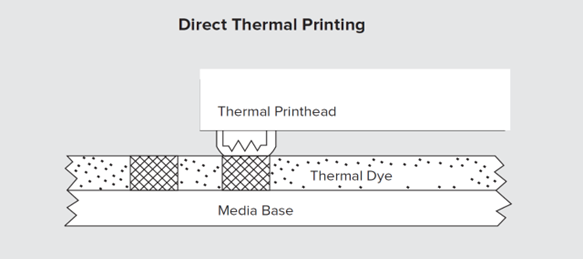

- Direct Thermal Printing

Direct thermal printing relies on heat-sensitive paper, labels that darken when exposed to heat. The printer contains a thermal printhead with hundred of individual heating elements. When media passes underneath the printhead, heat is selectively applied to the media (such as paper or synthetic labels), causing a chemical reaction that produces the desired image or text.

Pros:

- Simplicity: Direct Thermal printing eliminates the need for ribbons or ink cartridges, simplifying the printing process and reducing maintenance requirements.

- Cost-effective: Without the need for ribbons or inks, Direct Thermal printing is generally more cost-effective for applications with moderate print volumes.

- Speed: Direct Thermal printing tends to be faster than Thermal Transfer printing since it doesn't require the transfer of ink from a ribbon.

Cons:

- Sensitivity to environmental factors: Direct Thermal prints are susceptible to fading or darkening when exposed to heat, light, moisture, and certain chemicals. This makes them less suitable for long-term applications or environments with harsh conditions.

- Print durability: Direct Thermal prints can degrade over time, especially when exposed to environmental factors, which may affect the legibility of the printed content.

- Limited colour options: Direct Thermal printing is primarily limited to black or grayscale prints, making it less suitable for applications that require colour labels or images.

- Both Thermal Transfer and Direct Thermal printing have their advantages and limitations, and the choice between the two depends on factors such as print volume, durability requirements, colour needs, and budget considerations.

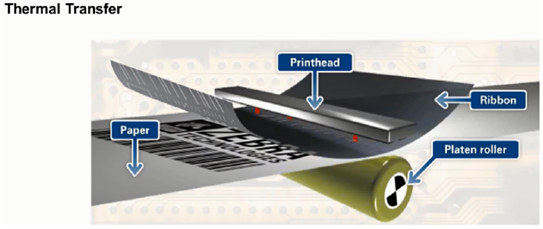

2. Thermal Transfer Printing

Thermal Transfer printing involves the process of transferring ink from a ribbon onto the printing material using heat. The printer contains a thermal printhead that consists of tiny heating elements arranged in a grid pattern. An ink ribbon made of polyester film coated with ink or wax-based substance passes between the printhead and the printing material (such as paper or synthetic labels & tags).

When the printhead heats up, the ink on the ribbon melts and transfers onto the printing material, creating a precise image or text on the face material.

Pros:

- Durability: Thermal Transfer prints are generally more resistant to fading, smudging, and scratching, making them suitable for applications where longevity is important.

- Versatility: Thermal Transfer printing can be used on various materials, including paper, polyester, polypropylene, fabric and much more.

- High-quality prints: The use of ribbons allows for precise and high-resolution prints, resulting in sharp and clear images or text.

- Wide colour options: Thermal Transfer printers can utilise coloured ribbons, enabling the printing of labels or tags in various colours.

Cons:

- Management - When supplies need replacing you have two types of media to change over and also to manage stocks of.

- Additional supplies: The use of ribbons necessitates keeping stock of different colours and types can increase maintenance and inventory costs.

- Ribbon compatibility: The printer, print media and ribbon must all be compatible to ensure optimal performance and print quality.

Thermal Transfer - Ink Ribbons

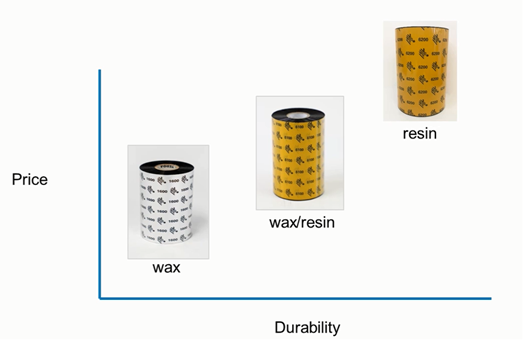

Ink ribbons are required for any non direct thermal print media and they tend to fall within 3 main categories based on their composition:

- Wax - Low cost printing applications usually for paper based media

- Wax Resin - Advanced printing for professional & branded print media applications

- Resin - Permanent & Specialist print applications such as asset labels, outdoor tags and chemical resistant labels.

For all of the above grades the width of the ribbons is an important factor to help minimise waste and optimise printing efficiency by choosing the right size

for the media being printed.

It's also worth noting the different types of printer hardware have limitations on the width and length of the ink ribbons being used within them, and some have specific requirements for the way the ink is coated on the rolls (either inside or outside) so it's best to check with an expert before buying any type of new stock.

Print Media

When it comes to actual printed media, there are many different types varying from simple self adhesive labels, up to more durable and robust non adhesive materials.

Some common examples:

- Paper Labels - A versatile and cost-effective material for label printing applications. It comes in different weights and finishes, such as gloss, matte, or uncoated. Paper labels are suitable for applications that don't require high durability or resistance to moisture or chemicals. They are commonly used for product packaging, address labels, and for any short-term identification applications.

- Vinyl labels are made from a durable synthetic material called polyvinyl chloride (PVC). They are highly resistant to water, oil, UV rays, and chemicals, making them suitable for both indoor and outdoor applications. Vinyl labels are often used for product labelling, outdoor signage, industrial equipment, and asset tracking.

- Polyester labels are made from a polyester film consisting of multiple layers. They offer excellent durability, resistance to tearing, moisture, chemicals, and temperature fluctuations. Polyester labels are commonly used in harsh environments, such as industrial settings, electronic components, medical devices, and automotive applications.

- Polypropylene Labels are made from a lightweight, flexible, and durable plastic material and are resistant to moisture, oils, chemicals, and tearing. Polypropylene labels are commonly used for packaging, food and beverage labelling, cosmetic products, and applications requiring resistance to water and oil.

- Polyethylene - Commonly known as PET and this is usually supplied as a thicker material compared to standard synthetic material (up to 300 microns) and is typically supplied as a non adhesive material that can be stapled or nailed to wood products for outdoor applications.

The Benefits of getting the right print combination for your business’s

needs:

- Minimised Misprints and Waste: By choosing the right hardware, businesses can reduce errors and wastage. Auto ID printers have advanced features like precise print alignment, automatic error detection, and calibration, preventing misprints and unnecessary waste, leading to cost savings.

- Improved Product Quality and Customer Satisfaction: Opting for the appropriate printer, ink ribbons, and label materials ensures consistent print quality, precise labelling, and enhanced barcode readability. This attention to detail reduces waste and enhances the overall customer/consumer experience.

- Efficient Workflow and Time Savings: Efficient printers with high-speed capabilities can handle large print volumes swiftly. Additional features like automatic label peeling, cutter attachments, and label rewinders help further streamline labelling processes, saving valuable time. Investing in the right printer boosts productivity, meets deadlines, and optimises resource allocation, resulting in significant time savings.

- Reduced Maintenance and Repair Costs: Selecting printers suited to specific business needs minimizes breakdowns and maintenance issues, reducing additional expenses. We recommend printers known for durability and performance, minimizing maintenance and repair costs, ultimately enhancing their cost-effectiveness.

In conclusion, there are so many different factors to consider when looking to purchase label printers and supplies.

At HUB Auto ID we can help you make informed decisions for the most cost-effective print operations tailored specifically for your business. In addition to hardware we can also provide a complete solution that includes software, installation, and repair services to help keep your printer operational at all times.